One-Piece Pickleballs

One-piece pickleballs are the gold-standard for tournament-style pickleballs that fly straight and have more predictable bounces off the court and more predictable hits off your paddle.

They are produced using a rotation molding process. When you think rotation molding, think layers.

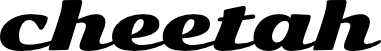

Virgin material and powdered colorant are poured into a mold. The mold is then bolted tight, placed in an oven and rotated at an even speed on a 3-dimensional axis. In this way, the plastic is laid down in thin layers of even thickness (2mm) without a seam.

After the material is baked, the plastic is cooled inside the mold, ensuring it hardens evenly and then extracted. Holes are then drilled with a computer numerical control (CNC) machine.

Two-Piece Pickleballs

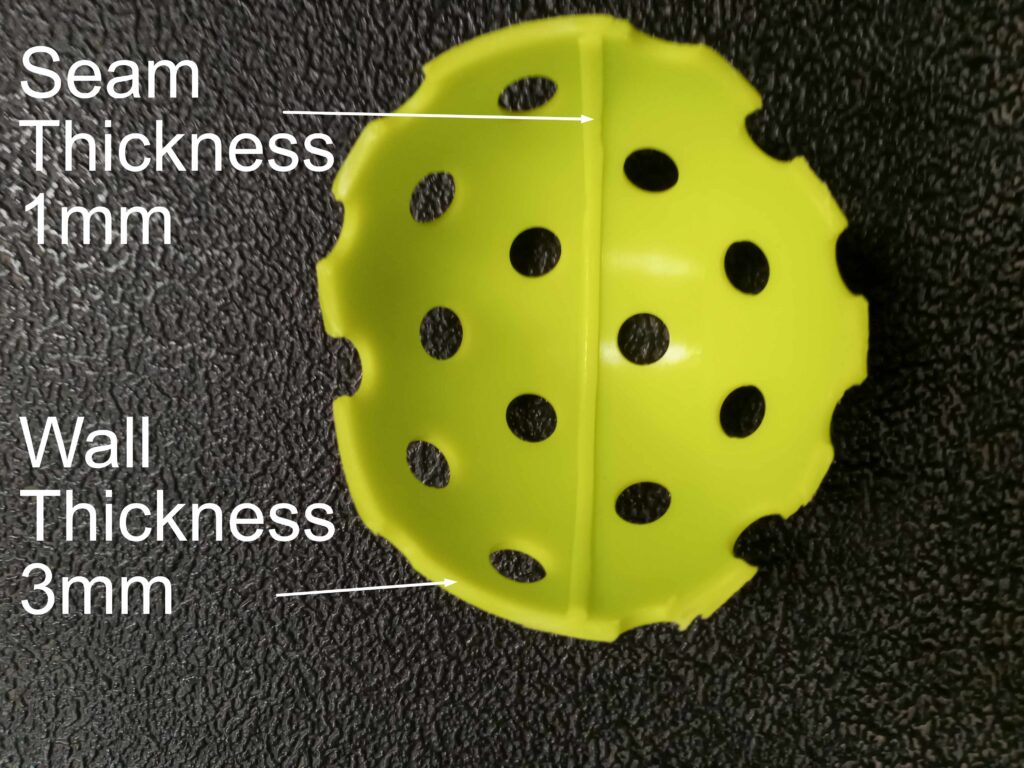

Two-piece pickleballs are the result when an injection molding process is used. These balls use a softer type of plastic, have thicker walls (3mm) and a seam running around the inside of the ball.

When manufacturing injection molded pickleballs, the material is melted and slowly forced into two stationary hemisphere molds under high pressure. This process then utilizes pressure to distribute the material throughout the molds, ensuring coverage of the molds’ entire shape.

The two hemispheres are fused together and a seam is created on the inside of the pickleball, increasing thickness (+1mm) and weight along the seam by more than 30%. This uneven wall thickness and weight leads to less predictable ball flights, bounces and hits, dramatically decreasing the ball’s performance.

Some players prefer them because they’re softer when hit. Others think these balls play too slow and feel like sandbags.

The Cheetah® M45 Pickleball

The Cheetah® M45 uses a rotational molding process, resulting in a one-piece, seamless pickleball with an even wall thickness, straight flights, predictable bounces and hits. It’s fast and performs as well as the other tournament-style pickleballs and has been approved by USA Pickleball for tournament play.

But Cheetah® M45s have a medium compression, as opposed to the high compression for other tournament-style balls. This medium compression makes the Cheetah® M45 more comfortable to hit and gives you a better feel.

A pickleball’s compression is determined by the hardness of the plastic used and the wall thickness. Plastic hardness is measured by a Shore D Durometer. USA Pickleball requires that pickleballs measure a 40 to 50 on a Shore D Durometer. It uses a 1 to 100 scale, where the higher the number, the harder the plastic.

The Cheetah® M45 measures a 45 (The M stands for medium compression and the 45 is the actual hardness measurement.) Some other tournament-style pickleballs measure a 50.

This somewhat softer plastic provides additional elasticity and gives the Cheetah® M45 a medium compression that feels more comfortable to hit. The M45s are also less likely to crack, compared to the harder, high compression pickleballs.

So, you’re really getting the best of both worlds with the Cheetah® M45. It’s fast and performs like the other tournament-style pickleballs, but M45s are more comfortable to hit and won’t crack nearly as often.

| Brand | Type | wall | Compression |

|---|---|---|---|

| Cheetah M45 | One-Piece | 2mm | Medium |

| Dura Fast 40 | One-Piece | 2mm | High |

| Franklin X-40 | One-Piece | 2mm | High |

| ONIX Fuse G2 | Two-Piece | 3mm* | Low |

| Penn 40 | Two-Piece | 3mm* | Low |